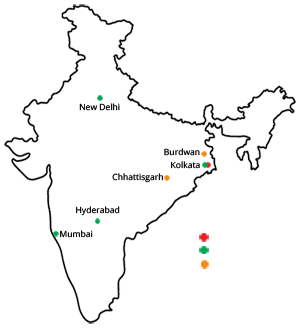

TMT Bars, under the brand name Balaji Shakti Thermex TMT Bar, used in Civil Construction, is manufactured by us at our Integrated Steel Plant facility in Durgpaur, West Bengal. We have an annual capacity of 260,000 MTs of TMT Bars and produce them using the Thermex technology for rapid water quenching from Hennigsdorfer Stahl Engineering GmbH, Germany.

Being an Integrated Steel Plant with both Blast Furnace and Electric Arc Furnace facilities available with us in the same premises, we are in a unique position to offer materials with low Sulphur and Phosphorous elements in Steel. Indeed, such facilities are absent amongst all manufacturers of TMT Bars in Durgapur, West Bengal, in the private sector.